Valve Casting Product Range

Comprehensive range of investment cast valve components for all pressure classes

Gate Valve Bodies

Solid and split body gate valve castings with precision seating surfaces.

Globe Valve Bodies

Y-pattern and angle globe valve bodies with integral seat designs.

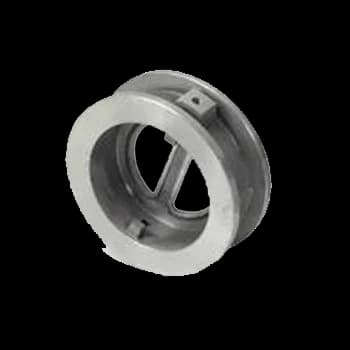

Check Valve Bodies

Swing, lift, and tilting disc check valve castings for various applications.

Ball Valve Bodies

One-piece, two-piece, and three-piece ball valve body castings.

Butterfly Valve Bodies

Wafer, lug, and double flanged butterfly valve casting designs.

Valve Bonnets

Bolted, welded, and pressure seal bonnets with precision bore.

Valve Discs & Wedges

Solid, flexible, and split wedge designs with hard-faced seating.

Valve Stems & Components

Precision valve stems, glands, and internal components.

Control Valve Bodies

Globe, angle, and specialty control valve body castings.

Safety Valve Parts

Safety and relief valve bodies, bonnets, and nozzles.

Specialty Valve Components

Custom valve components for critical applications.

Valve Types We Serve

Casting solutions for all major valve categories

Valve Casting Materials

Wide range of alloys to match your valve application requirements

Carbon Steel

WCB, WCC, LCB, LCC, LCA

General purpose, oil & gas, water

Alloy Steel

WC6, WC9, C5, C12, CA15

High temperature, steam, power

Stainless Steel

CF8, CF8M, CF3, CF3M, CK20, CN7M

Chemical, food, pharmaceutical

Duplex Steel

CD4MCU, 4A, 5A, 6A, CE8MN

Offshore, desalination, marine

Nickel Alloys

CY40, Monel, Inconel, Hastelloy

Corrosive chemicals, high temp

Bronze & Brass

LG2, LG4, AB2, Gun Metal

Marine, seawater, fire systems

Valve Casting Applications

Why Choose Us for Valve Casting?

Pressure Rated

Castings designed and tested for pressure classes from 150# to 2500# ANSI.

Temperature Range

Materials for cryogenic (-196°C) to high temperature (+650°C) applications.

PED Certified

PED 2014/68/EU certified for European pressure equipment requirements.

Precision Seating

Tight tolerance seating surfaces for leak-free valve operation.

Hydro Tested

100% hydrostatic testing per API 598 / EN 12266 standards.

Full Traceability

Complete material traceability with EN10204 3.1/3.2 certificates.