Steel Castings India

Neocast Alloys is a leading manufacturer of precision steel castings in India. From carbon steel to super duplex, we deliver ISO certified, export quality castings for industries worldwide.

What are Steel Castings?

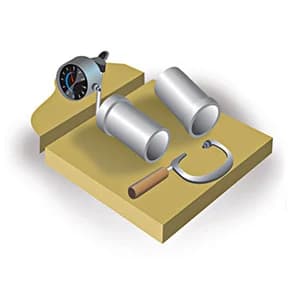

Steel castings are solid metal components manufactured by pouring molten steel into precisely designed molds. This process allows for the creation of complex shapes with excellent mechanical properties that cannot be achieved through forging or machining alone.

At Neocast Alloys, we specialize in investment casting (lost wax process) - a precision manufacturing technique that delivers superior dimensional accuracy, excellent surface finish, and the ability to cast intricate geometries with minimal material waste.

Our steel castings serve critical applications across valve, pump, marine, automotive, and general engineering industries worldwide.

Types of Steel Castings We Manufacture

We pour over 50+ grades of ferrous and non-ferrous metals, delivering customized solutions for diverse industrial requirements.

Carbon Steel Castings

High-strength carbon steel castings ideal for general engineering applications. Excellent machinability and weldability with superior mechanical properties.

Alloy Steel Castings

Premium alloy steel castings with enhanced properties including wear resistance, heat resistance, and corrosion resistance for demanding applications.

Stainless Steel Castings

Corrosion-resistant stainless steel castings perfect for chemical processing, food industry, and marine applications with excellent surface finish.

Duplex Steel Castings

Advanced duplex and super duplex stainless steel castings combining excellent strength with superior corrosion resistance for offshore and chemical industries.

Other Steel Grades We Manufacture

9-Step Steel Casting Manufacturing Process

Our investment casting process combines traditional craftsmanship with modern technology to deliver precision steel castings.

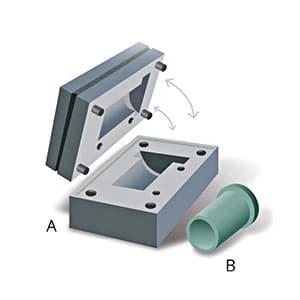

Tooling & Die Making

Tooling & Die Making

Precision aluminum or steel dies are crafted using CAD/CAM technology to create accurate wax patterns.

Tooling & Die Making

Precision aluminum or steel dies are crafted using CAD/CAM technology to create accurate wax patterns.

Wax Pattern Injection

Wax Pattern Injection

Molten wax is injected into dies under controlled temperature and pressure to produce dimensionally accurate patterns.

Wax Pattern Injection

Molten wax is injected into dies under controlled temperature and pressure to produce dimensionally accurate patterns.

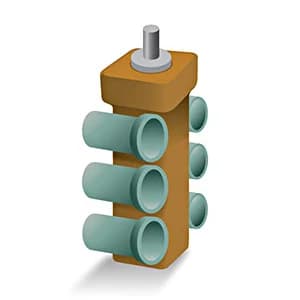

Pattern Assembly

Pattern Assembly

Multiple wax patterns are assembled onto a central wax sprue (tree) for efficient multi-component casting.

Pattern Assembly

Multiple wax patterns are assembled onto a central wax sprue (tree) for efficient multi-component casting.

Ceramic Shell Building

Ceramic Shell Building

The wax assembly is dipped in ceramic slurry and coated with refractory sand to build a strong shell mold.

Ceramic Shell Building

The wax assembly is dipped in ceramic slurry and coated with refractory sand to build a strong shell mold.

Dewaxing (Lost Wax)

Dewaxing (Lost Wax)

The ceramic shell is heated to melt and drain the wax, leaving a precise hollow mold cavity.

Dewaxing (Lost Wax)

The ceramic shell is heated to melt and drain the wax, leaving a precise hollow mold cavity.

Shell Firing

Shell Firing

The empty shell is fired at high temperatures (1000-1100°C) to achieve maximum strength and remove residual wax.

Shell Firing

The empty shell is fired at high temperatures (1000-1100°C) to achieve maximum strength and remove residual wax.

Metal Pouring

Metal Pouring

Molten steel is poured into the preheated ceramic mold under controlled conditions ensuring complete fill.

Metal Pouring

Molten steel is poured into the preheated ceramic mold under controlled conditions ensuring complete fill.

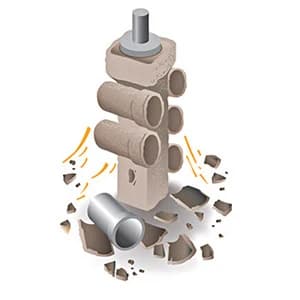

Shell Knockout & Finishing

Shell Knockout & Finishing

After cooling, the ceramic shell is removed. Castings undergo gate cutting, grinding, and precision machining.

Shell Knockout & Finishing

After cooling, the ceramic shell is removed. Castings undergo gate cutting, grinding, and precision machining.

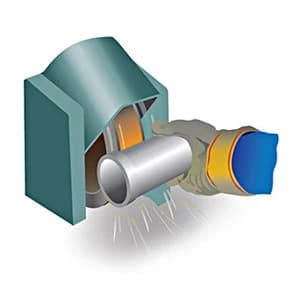

Quality Testing & Dispatch

Quality Testing & Dispatch

Every casting undergoes rigorous NDT testing, dimensional inspection, and material analysis before delivery.

Quality Testing & Dispatch

Every casting undergoes rigorous NDT testing, dimensional inspection, and material analysis before delivery.

Steel Casting Applications

Our steel castings serve critical roles across diverse industries worldwide.

Why Choose Our Steel Castings?

Partner with a trusted steel casting manufacturer in India committed to quality, precision, and customer satisfaction.

ISO 9001:2015 Certified

Internationally recognized quality management system ensuring consistent, high-quality steel castings.

State-of-the-Art Facility

Modern foundry in Gujarat equipped with advanced machinery and in-house testing laboratory.

Global Export Quality

Exporting premium steel castings to industries worldwide with international quality standards.

369+ Happy Customers

Trusted by leading companies across valve, pump, automotive, and engineering industries.

On-Time Delivery

100% on-time delivery commitment with efficient production planning and logistics.

Complete Solutions

From design to delivery - casting, machining, heat treatment, and NDT testing under one roof.