Precision Technologies

Advanced CNC machining capabilities tailored for cast components

CNC Turning

High-precision turning for shafts, flanges, and cylindrical components. Capable of handling diameters up to 800mm.

VMC Milling

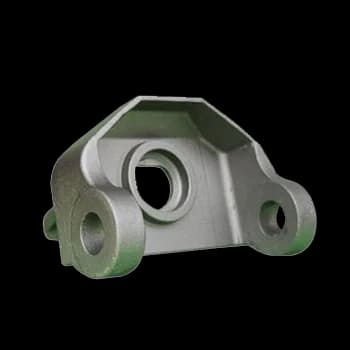

3, 4, and 5-axis milling for complex geometries, gearbox housings, and valve bodies with tight positional tolerances.

Precision Grinding

Surface and cylindrical grinding to achieve Ra 0.4 finish and sub-micron dimensional accuracy for critical fits.

Drilling & Tapping

Multi-spindle drilling and rigid tapping for mounting holes, flanges, and complex bolt patterns.

Why Integrated Machining?

Single Accountability

One partner responsible for both casting quality and machined dimensions, eliminating blame-games.

Reduced Lead Time

Parallel processing of casting and machining planning significantly shortens overall delivery timeline.

Scrap Reduction

Machining allowances are optimized, and internal defects are detected early in the process.

Cost Efficiency

Integrated logistics and reduced handling lower the total cost of ownership for finished parts.

Quality in Every Micron

Rigorous quality control and advanced inspection methodologies

Micron Precision

Capable of maintaining IT6-IT7 tolerance grades on critical dimensions.

CAD/CAM

Advanced CAM software for generating optimized tool paths directly from 3D models.

CMM Inspection

Coordinate Measuring Machine verification for complex geometries and GD&T.

Prototyping

Rapid machining of soft-tooling samples for quick design validation.

Fixture Design

In-house design and fabrication of custom hydraulic fixtures for repeatability.

Surface Finish

Controlled surface finish Ra values for sealing faces and bearing journals.