Pump Part Casting Range

Comprehensive range of investment cast pump components for diverse applications

Pump Impellers

Open, semi-open, and closed impellers with precise hydraulic profiles for optimal efficiency.

Pump Casings

Volute casings, diffuser casings, and split casings with excellent surface finish.

Pump Diffusers

Precision diffusers for multi-stage pumps with accurate vane angles and profiles.

Wear Rings

Wear rings with close clearances for efficient pump operation and longevity.

Pump Bowls

Bowl assemblies for vertical turbine and submersible pumps with precision bore.

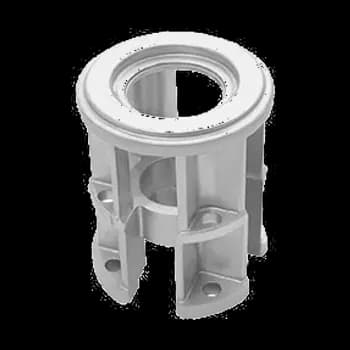

Pump Components

Shaft sleeves, bushings, bearing housings, and other precision pump parts.

Pump Types We Serve

Casting solutions for all major pump categories

Pump Casting Materials

Wide range of corrosion-resistant and high-performance alloys for pump applications

Stainless Steel

CF8, CF8M, CF3, CF3M, CK20, CN7M

Water pumps, chemical pumps, food industry

Duplex Steel

CD4MCU, 4A, 5A, 6A, CE8MN

Seawater, desalination, offshore

Carbon Steel

WCB, WCC, LCB, LCC

General purpose, oil & gas

Alloy Steel

WC6, WC9, C5, C12

High temperature, steam

Nickel Alloys

Monel, Inconel, Hastelloy

Aggressive chemicals, high temp

Bronze & Copper

AB2, Gun Metal, Navy Brass

Marine, seawater, corrosion resistant

Pump Casting Applications

Why Choose Us for Pump Casting?

Hydraulic Precision

Precise vane profiles and hydraulic passages for optimal pump efficiency and performance.

Corrosion Resistant

Wide range of corrosion-resistant alloys including duplex, super duplex, and nickel alloys.

Pressure Tested

Hydrostatic pressure testing and NDT inspection ensure leak-free, reliable components.

Temperature Range

Materials rated for cryogenic to high-temperature applications up to 1100°C.

Complete Machining

In-house CNC machining for ready-to-assemble pump components with tight tolerances.

Industry Certified

ISO 9001:2015, PED certified with complete material traceability and documentation.